The real-time, dynamic filling level system

When you manage waste flows, you want to be sure that you take care of emptying in time and make optimal use of transport capacity. If a container is far from full in the morning, it might easily be full in the afternoon and needs quickly to be emptied. Our intelligent Octopus communication system gives you insight and helps you to look ahead.

The 8 skills of Octopus

Real-time dynamic filling level system

Grip on your schedule

you to anticipate and plan proactively

by remotely adjusting the almost-full notification. This also sets the almost-full signal lamp on the compactor, so that the user has the same optical signal as you have.

Universally applicable

Sustainable through fewer transport movements

Completely inhouse and remotely adjustable

Completely inhouse and remotely adjustable

Security and data safety guaranteed

Security and data safety guaranteed

The data you collect are your date; the hosting of the server is entirely in-house by De Rooij and we comply with the highest certification and information security

Smart maintenance history

Smart maintenance history

Automatic reminder inspection

Automatic reminder inspection

Real-time dynamic filling level system

Thanks to the real-time insight into the filling level, you can see exactly the percentage the press container is filled with at any time.

Grip on your schedule

Grip on your schedule Agenda Insight into the real-time fill rate allows you to anticipate and plan proactively by remotely adjusting the almost-full notification. This also sets the almost-full signal lamp on the compactor, so that the user has the same optical signal as you have.

Universally applicable

Our Octopus can be installed on any kind and brand of compactors without limitations in its operation.

Sustainable through fewer transport movements

Fewer truck rides mean less CO2 emissions per kilo of residual waste.

Completely inhouse and remotely adjustable

As user you manage your own users, locations, email-addresses and your desired almost-full notification.

Security and data safety guaranteed

The data you collect are your date; the hosting of the server is entirely in-house by De Rooij and we comply with the highest certification and information security

Smart maintenance history

Octopus is effective in case of faults and repairs: you can keep a detailed maintenance history on the Octopus Website.

Automatic reminder inspection

One month before the inspection has expired or the compactor is due for periodic maintenance, the Octopus automatically sends a reminder.

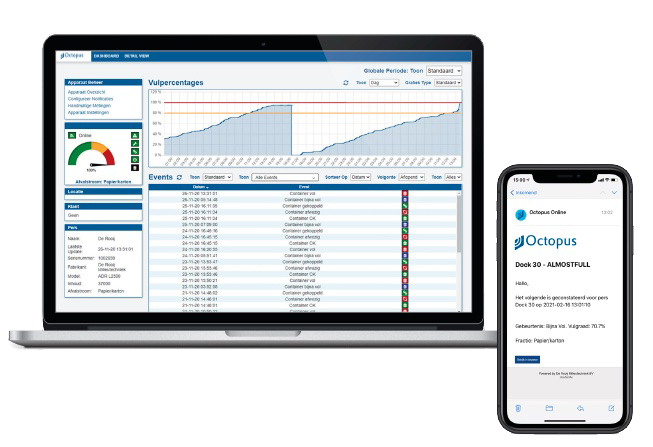

Octopus provides insight!

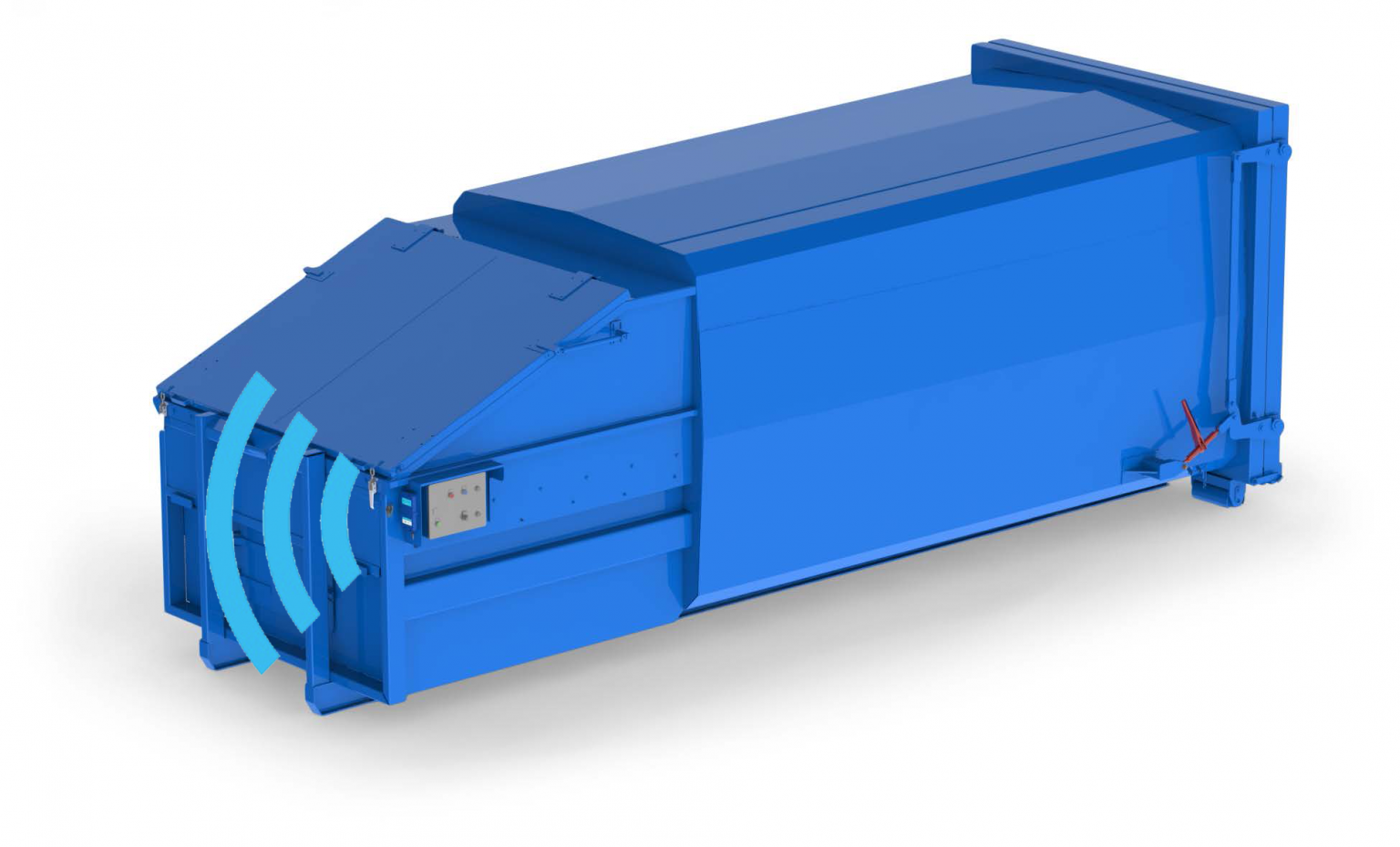

An octopus is special. To name a few characteristics: its blood is blue it is intelligent and agile. Its body may be small but the reach of its eight arms is enormous. It feels at home all over the world, adapts to its environment and communicates in colour. And so does our Octopus. It is the real-time, dynamic filling rate system, smart and self-learning, specially developed for every brand and type of waste compactor. The combination of a compact communication module with a web-based application provides insight, ease of use and data security. As it is a web-based application, no installation is required and it can be accessed via any computer or a smartphone with a browser. When a user logs in, he can see all the crucial information of his installations at a glance. First of all the percentage of the full report bit also notifications and current status. You can then access the installation history in detail, such as measured pressures, emergency stops and other activities. The entire application is available in Dutch, English, French and German.

Optional with GPS function

If you use a rotation system with portable compactors, Octopus can be expanded with a GPS function. So you know where the portable packer is located at any time.

Octopus: extensive grip on residues

Strong equipment

The compact Octopus communication module has an impact-resistant and waterproof housing. It is easy to install on new and existing installations. The powerful external antenna guarantees range, even in indoor dock shelter setups, for example. The software is hosted in a state-of

te art data center that meets the highest certifications; information and data are maximally secured. All facilities, such as server, fiber optic connections and emergency power supply facilities have been set up redundantly,

so that maximum up-time is guaranteed.

Simple management

You can manage the settings, names and notifications via the website yourself without the intervention of an external party; for example, you can set the moment and the notifications of the near-full notification yourself. You can also keep track of the maintenance history and you will automatically receive a reminder for the inspection.